Maximise efficiency with seamless PDM and ERP Integration

We have found that many manufacturing and retail companies today use a PDM (Product Data Management) system. This is particularly relevant for companies working with complex products requiring extensive documentation and version control, as well as companies needing to manage product information for many items. Since the PDM and ERP (Enterprise Resource Planning) systems rely on some of the same data, we have developed integrations that automate manual processes, allowing our customers to focus on their core business.

Practical examples of the integration:

As mentioned, PDM and ERP solutions share some critical data that is essential for both product development and other parts of the value chain in manufacturing companies. This integration covers the following:

- Product data: For example, drawings, specifications, and files related to a product.

- BOM (Bill of Materials): lists that show all components and materials needed to manufacture the product.

- Documentation: manuals, certificates, and other documents related to a product, which are necessary not only in production but also in sales and other parts of the value chain.

- Change history: any changes made during the design or production process must be shared so that everyone works with the same data.

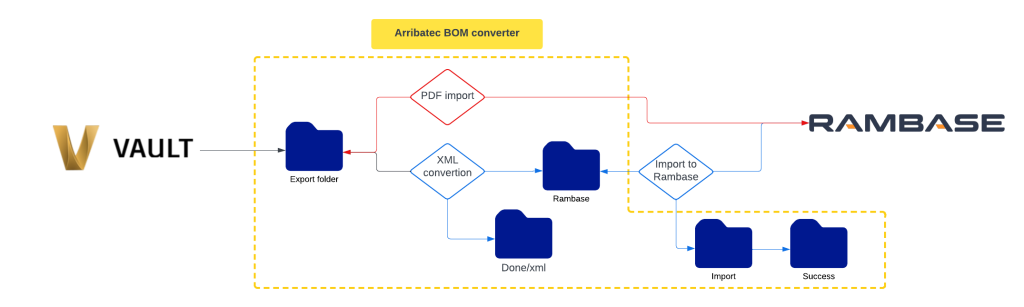

Example of how we have set up the flow between Autodesk Vault and Rambase ERP

Valuable benefits from the integration:

Efficiency, automation, and data quality: imagine design changes made by engineers in the PDM system automatically providing production operators with accurate bills of materials and instructions. IT solutions should enhance employee experiences—in this case, by providing a sense of control and eliminating uncertainty around data quality. Errors often arise from manual work, which can be avoided through integration. Changes in PDM are synchronized with ERP during revisions, and new products and drawings are automatically generated in ERP.

Inventory optimization: When the ERP system receives updated bills of materials from PDM, automatic purchase orders for required materials can be created, reducing the risk of stock shortages and production stoppages.

Traceability: The integration enables tracking of components from the design phase to the finished product. This can make it easier to maintain quality control, such as in cases where product recalls are necessary.

Planning and production: With updated data from PDM in ERP, planning based on materials and resources becomes smoother, leading to a more consistent production flow and reduced downtime. The integration also transfers drawings so that operators always have the correct version of the production documents.

Aukra Maritime AS has implemented Rambase ERP and integration with Autodesk Vault via the Rambase team at Arribatec:

“By integrating Autodesk Vault with Rambase ERP, we have automated many previously manual operations. This has given us better control and an overview of current BOM (Bill Of Material), which provides us with a better understanding of the purchasing and production processes.”

Freddy Løvik, Development Manager, Aukra Maritime AS

Productivity in companies must increase, and this is an example of digitalization by eliminating time spent on unnecessary tasks. Contact us if you would like to know more about the integration between PDM and Rambase ERP.